Work Size up to 9mL x 2mH x 1.5mW x 6 Tons Weight

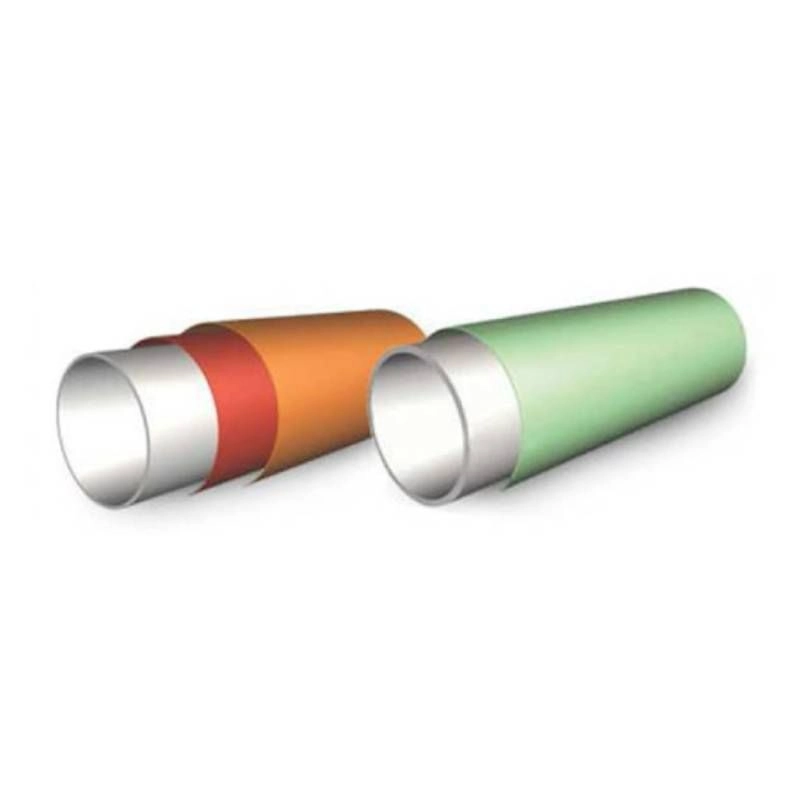

Bends and fittings coating line includes the process of material handling through blasting chamber, oven chamber and powder spray booth. Anti-corrosion coating applicable here is Fusion Bonded Epoxy (FBE) and 3 Layer Polyethylene/Polypropylene (3LPP).

Shown below is the system specially designed & constructed on turnkey basis for PetroVietnam (PVID)

Monorail Hanger at Loading Bay, Loading Long Radius Pipe Bend, Going Through Blast Room & Heating Oven

In current practice, there are three common anti-corrosion coating methods, including Asphalt Enamel (AE) coating, FBE and 3LPE/PP method combined with FBE. AE method has not been used in developed countries for AE is dependent on oil price since the coating material is a petroleum products. Beside having adverse impact on the environment, AE has higher cost of implementation and maintenance while life span of AE pipes is shorter than those in other advanced coating methods.

Spray Booth is immediately after the heating oven & the result is the 3 Layer Polyethylene/Polypropylene finish

Weblast has been consulted for the turnkey construction of this coating plant, begining in July 2011 and completely installed & commssioned in Nov 2011. Among other equipment installed are,

- The ground handling trolley for the blast cleaning process

- A fully equiped full floor recovery blast room installed with 2 blast guns and dust collector unit

- A gas fired recirculation oven capable of heating up to 250 Deg C with even temperature control

- The main burner system is from Maxon with uniform air distribution duct works and gas piping

- Two units of Gema twin guns powder spray equipment are used for the spray booth

- Other equipment are the Ingersoll Rand compressed air system, powder recirculation cyclon collector & dust collector with safe explosion vent setup.

Inquiry - FBE & 3LPP Coating System